Voir les spécifications pour les détails du produit.

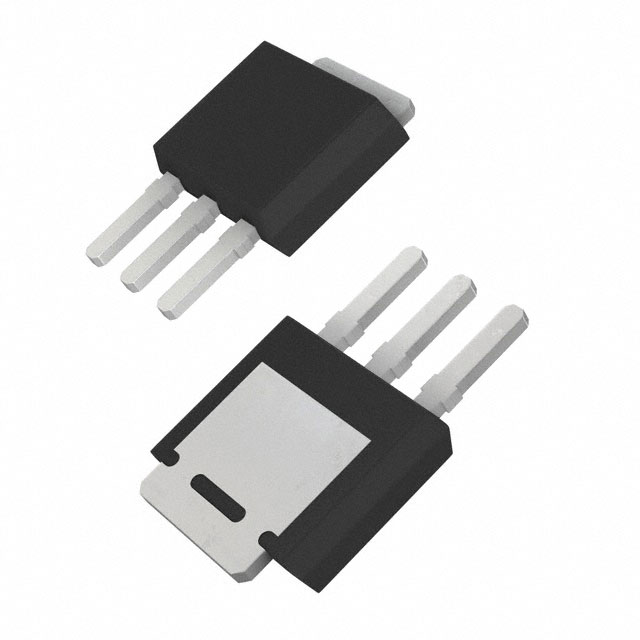

AOI4S60

Product Overview

Category: Integrated Circuit

Use: AOI4S60 is a high-speed quad-channel opto-isolator with Schmitt-trigger inputs. It is commonly used for signal isolation and level shifting in various electronic applications.

Characteristics: The AOI4S60 features high speed, low power consumption, and high noise immunity. It comes in a small package and offers reliable performance.

Package: The AOI4S60 is available in a small outline integrated circuit (SOIC) package.

Essence: This product serves as a crucial component for isolating and interfacing digital signals in electronic circuits.

Packaging/Quantity: The AOI4S60 is typically sold in reels containing 250 units.

Specifications

- Isolation Voltage: 5000 Vrms

- Propagation Delay: 50 ns

- Supply Voltage Range: 3V to 5.5V

- Operating Temperature Range: -40°C to 85°C

- Input Current: 5 mA

- Output Current: 50 mA

Detailed Pin Configuration

The AOI4S60 has a standard pin configuration with four input pins and four output pins. The pinout is as follows: 1. Input 1 2. Input 2 3. Input 3 4. Input 4 5. Ground 6. Output 1 7. Output 2 8. Output 3 9. Output 4 10. VCC

Functional Features

- High-speed opto-isolation

- Schmitt-trigger inputs for noise immunity

- Quad-channel design for multiple signal isolation

- Low power consumption

Advantages and Disadvantages

Advantages: - High-speed operation - Reliable signal isolation - Low power consumption - Noise immunity

Disadvantages: - Limited output current capacity - Operating temperature range may not be suitable for extreme environments

Working Principles

The AOI4S60 utilizes opto-isolation technology to transfer digital signals between two electrically isolated circuits. The Schmitt-trigger inputs ensure that the device can tolerate noisy input signals without false triggering.

Detailed Application Field Plans

The AOI4S60 is widely used in industrial automation, motor control systems, power inverters, and digital communication equipment. It is also employed in automotive electronics and medical devices where signal isolation and noise immunity are critical.

Detailed and Complete Alternative Models

- AOI4S30: Similar specifications with lower isolation voltage

- AOI4S80: Higher isolation voltage and wider operating temperature range

- AOI4S90: Enhanced noise immunity and higher output current capacity

In conclusion, the AOI4S60 is a versatile opto-isolator that provides high-speed signal isolation and level shifting capabilities for various electronic applications. Its compact size, low power consumption, and noise immunity make it an ideal choice for modern digital systems.

Word Count: 410

Énumérez 10 questions et réponses courantes liées à l'application de AOI4S60 dans les solutions techniques

What is AOI4S60?

- AOI4S60 is an advanced optical inspection system designed for high-speed and high-accuracy inspection of electronic components and assemblies.

How does AOI4S60 improve quality control in electronics manufacturing?

- AOI4S60 uses advanced imaging technology to detect defects such as soldering issues, component misalignment, and other assembly problems, leading to improved quality control.

What types of defects can AOI4S60 detect?

- AOI4S60 can detect defects such as solder bridges, insufficient solder, missing components, wrong polarity, and other common assembly issues.

Can AOI4S60 be integrated into automated production lines?

- Yes, AOI4S60 is designed for seamless integration into automated production lines, providing real-time inspection without slowing down the manufacturing process.

What are the key features of AOI4S60?

- Key features of AOI4S60 include high-resolution imaging, advanced defect detection algorithms, intuitive user interface, and compatibility with various PCB sizes and types.

Is AOI4S60 suitable for small-scale production as well?

- Yes, AOI4S60 is versatile and can be used for both small-scale and large-scale production, offering consistent and reliable inspection capabilities.

Does AOI4S60 support traceability and data logging?

- Yes, AOI4S60 provides traceability by capturing and logging inspection data, including images and defect details, which can be used for analysis and process improvement.

What are the maintenance requirements for AOI4S60?

- Regular cleaning of the imaging system and calibration checks are recommended for maintaining the performance and accuracy of AOI4S60.

Can AOI4S60 be customized for specific inspection requirements?

- Yes, AOI4S60 can be customized to adapt to specific inspection criteria and requirements based on the type of electronic assemblies being produced.

What technical support options are available for AOI4S60 users?

- Users have access to technical support, training, and software updates from the manufacturer to ensure optimal performance and utilization of AOI4S60.