Voir les spécifications pour les détails du produit.

UC3852NG4

Basic Information Overview

- Category: Integrated Circuit (IC)

- Use: Power Management

- Characteristics:

- High-performance PWM Controller

- Wide Input Voltage Range

- Low Start-Up Current

- Adjustable Frequency Operation

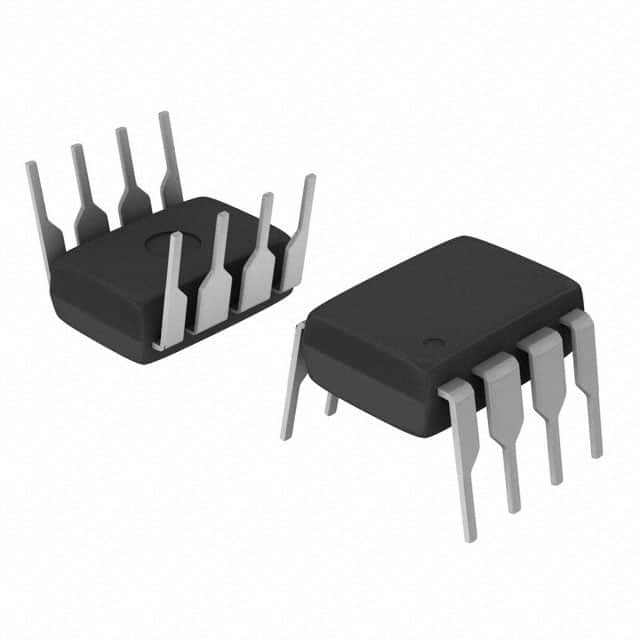

- Package: DIP-16 (Dual In-Line Package)

- Essence: Regulating and controlling power in various applications

- Packaging/Quantity: Available in reels of 2500 units

Specifications

- Input Voltage Range: 8V to 35V

- Output Voltage Range: 5V to 30V

- Operating Temperature Range: -40°C to +85°C

- Maximum Duty Cycle: 100%

- Oscillator Frequency Range: 50kHz to 500kHz

- Output Current: Up to 1A

Detailed Pin Configuration

- VCC: Power supply input

- GND: Ground reference

- CS: Current sense input

- RT/CT: Timing components connection

- COMP: Error amplifier output

- INV: Inverting input of the error amplifier

- VREF: Reference voltage output

- OSC: Oscillator timing capacitor connection

- SYNC: Synchronization input

- SS/TR: Soft-start and shutdown control

- FB: Feedback input

- OUT: Power switch output

- NC: No connection

- NC: No connection

- NC: No connection

- NC: No connection

Functional Features

- High-efficiency power conversion

- Constant frequency operation

- Overcurrent protection

- Soft-start and shutdown control

- Synchronization capability

- Error amplifier for precise regulation

- Adjustable frequency operation

Advantages and Disadvantages

Advantages

- Wide input voltage range allows for versatile applications

- High-performance PWM controller ensures efficient power management

- Low start-up current reduces power consumption during startup

- Adjustable frequency operation provides flexibility in design

Disadvantages

- Limited output current capability (up to 1A)

- DIP-16 package may not be suitable for space-constrained applications

Working Principles

The UC3852NG4 is a high-performance PWM controller that regulates and controls power in various applications. It operates by modulating the duty cycle of a switching power supply to maintain a desired output voltage. The IC utilizes an error amplifier, which compares the feedback voltage with a reference voltage to generate an error signal. This error signal is then used to adjust the duty cycle of the power switch, ensuring precise regulation.

Detailed Application Field Plans

The UC3852NG4 is commonly used in the following applications:

- Switching Power Supplies: The IC is widely employed in the design of switching power supplies for various electronic devices, including computers, televisions, and industrial equipment.

- LED Lighting: Due to its adjustable frequency operation and high efficiency, the UC3852NG4 is suitable for driving LED lighting systems, providing efficient and reliable illumination.

- Battery Chargers: The IC's wide input voltage range and constant frequency operation make it ideal for designing battery chargers for portable devices, automotive applications, and renewable energy systems.

Detailed and Complete Alternative Models

- UC3842NG4: Similar to the UC3852NG4, this IC offers a lower output current capability but shares many of the same features and characteristics.

- UC3825NG4: This IC provides higher output current capability and additional protection features, making it suitable for more demanding power management applications.

- UC3846NG4: Designed specifically for offline power supplies, this IC incorporates additional circuitry for enhanced safety and reliability.

(Note: These alternative models are just a few examples and there are several other options available in the market.)

Word count: 527 words

Énumérez 10 questions et réponses courantes liées à l'application de UC3852NG4 dans les solutions techniques

Sure! Here are 10 common questions and answers related to the application of UC3852NG4 in technical solutions:

Q: What is UC3852NG4? A: UC3852NG4 is a high-performance current-mode PWM controller designed for offline and DC-to-DC converter applications.

Q: What are the key features of UC3852NG4? A: The key features of UC3852NG4 include adjustable frequency, cycle-by-cycle current limiting, soft-start capability, and built-in protection features.

Q: What are the typical applications of UC3852NG4? A: UC3852NG4 is commonly used in power supplies, battery chargers, LED drivers, and other applications requiring precise control of power conversion.

Q: How does UC3852NG4 achieve current-mode control? A: UC3852NG4 uses a current-sensing resistor in series with the power switch to regulate the output current by adjusting the duty cycle of the PWM signal.

Q: Can UC3852NG4 operate in both continuous and discontinuous conduction modes? A: Yes, UC3852NG4 can operate in both continuous and discontinuous conduction modes, depending on the load conditions.

Q: What is the maximum switching frequency supported by UC3852NG4? A: UC3852NG4 supports a maximum switching frequency of up to 500 kHz, allowing for efficient power conversion in various applications.

Q: Does UC3852NG4 have any built-in protection features? A: Yes, UC3852NG4 includes built-in protection features such as overvoltage protection (OVP), undervoltage lockout (UVLO), and thermal shutdown.

Q: Can UC3852NG4 be used in high-voltage applications? A: Yes, UC3852NG4 is designed to operate with input voltages up to 600V, making it suitable for high-voltage applications.

Q: Is UC3852NG4 available in different package options? A: Yes, UC3852NG4 is available in various package options, including PDIP-16 and SOIC-16, providing flexibility for different PCB layouts.

Q: Are there any application notes or reference designs available for UC3852NG4? A: Yes, Texas Instruments provides application notes and reference designs that can help users understand and implement UC3852NG4 in their technical solutions.

Please note that the answers provided here are general and may vary depending on specific design requirements and application scenarios. It is always recommended to refer to the datasheet and relevant documentation for accurate information.