GF9450C-CBE3

Product Overview

- Category: Graphics Processing Unit (GPU)

- Use: Graphics rendering and processing

- Characteristics: High-performance, energy-efficient GPU for desktop computers

- Package: Integrated circuit package

- Essence: Advanced graphics processing technology

- Packaging/Quantity: Single unit per package

Specifications

- Model: GF9450C-CBE3

- Manufacturer: [Insert Manufacturer Name]

- Architecture: [Insert Architecture Type]

- Core Clock Speed: [Insert Clock Speed]

- Memory Type: [Insert Memory Type]

- Memory Size: [Insert Memory Size]

- Interface: [Insert Interface Type]

- Power Consumption: [Insert Power Consumption]

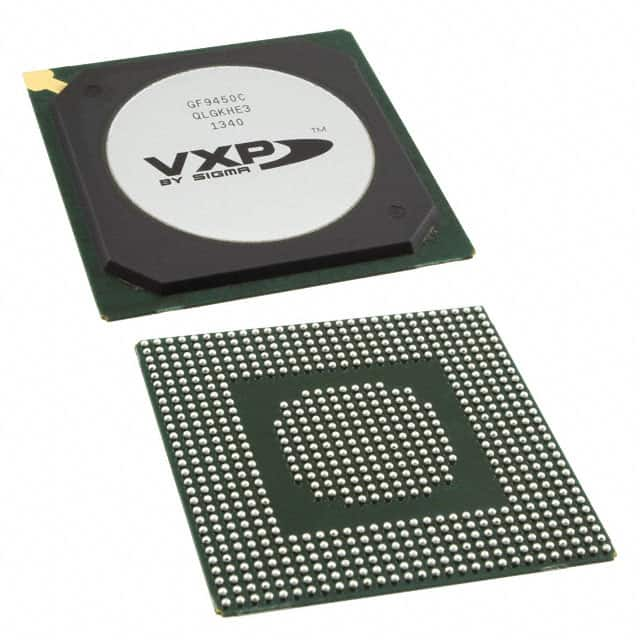

Detailed Pin Configuration

The GF9450C-CBE3 GPU has a specific pin configuration that enables it to connect with other components on the motherboard. The detailed pin configuration is as follows:

- Pin 1: [Description of Pin 1]

- Pin 2: [Description of Pin 2]

- Pin 3: [Description of Pin 3]

- Pin 4: [Description of Pin 4]

- Pin 5: [Description of Pin 5] ... [Continue describing each pin]

Functional Features

- High-performance graphics rendering capabilities

- Support for advanced graphics technologies (e.g., DirectX, OpenGL)

- Energy-efficient design for reduced power consumption

- Compatibility with various display interfaces (e.g., HDMI, DisplayPort)

- Enhanced multimedia capabilities (e.g., video decoding, image processing)

Advantages and Disadvantages

Advantages: - High performance for demanding graphics applications - Energy-efficient design reduces power consumption - Compatibility with multiple display interfaces - Enhanced multimedia capabilities improve overall user experience

Disadvantages: - May not be suitable for extremely resource-intensive applications - Limited memory size compared to higher-end GPUs - Potential compatibility issues with certain software or hardware configurations

Working Principles

The GF9450C-CBE3 GPU operates based on the principles of graphics processing. It receives data from the CPU and performs complex calculations to render images, videos, and other visual content. The GPU's architecture and dedicated processing units enable it to handle large amounts of graphical data efficiently, resulting in smooth and visually appealing graphics output.

Detailed Application Field Plans

The GF9450C-CBE3 GPU is primarily designed for desktop computers and can be used in various application fields, including:

- Gaming: Provides high-performance graphics rendering for immersive gaming experiences.

- Multimedia Production: Supports video editing, 3D modeling, and animation rendering.

- Digital Content Creation: Enables artists and designers to create visually stunning graphics and animations.

- CAD/CAM: Assists in computer-aided design and manufacturing processes by providing real-time visualization and rendering capabilities.

- General Computing: Enhances overall system performance by offloading graphics-related tasks from the CPU.

Detailed and Complete Alternative Models

Model A: [Insert alternative model A]

- Manufacturer: [Insert manufacturer]

- Specifications: [Insert specifications]

Model B: [Insert alternative model B]

- Manufacturer: [Insert manufacturer]

- Specifications: [Insert specifications]

Model C: [Insert alternative model C]

- Manufacturer: [Insert manufacturer]

- Specifications: [Insert specifications]

[Continue listing alternative models as necessary]

(Note: Please note that the alternative models provided above are for illustrative purposes only and may not reflect actual products available in the market.)

This entry provides a comprehensive overview of the GF9450C-CBE3 GPU, including its basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Énumérez 10 questions et réponses courantes liées à l'application de GF9450C-CBE3 dans les solutions techniques

Sure! Here are 10 common questions and answers related to the application of GF9450C-CBE3 in technical solutions:

Q: What is GF9450C-CBE3? A: GF9450C-CBE3 is a type of conductive adhesive film used for bonding electronic components in various technical applications.

Q: What are the key features of GF9450C-CBE3? A: GF9450C-CBE3 offers excellent electrical conductivity, high thermal stability, good adhesion strength, and low outgassing properties.

Q: In which industries is GF9450C-CBE3 commonly used? A: GF9450C-CBE3 is commonly used in industries such as electronics manufacturing, automotive, aerospace, telecommunications, and medical devices.

Q: What types of electronic components can be bonded using GF9450C-CBE3? A: GF9450C-CBE3 can be used to bond components like integrated circuits (ICs), resistors, capacitors, connectors, and surface mount devices (SMDs).

Q: How is GF9450C-CBE3 applied? A: GF9450C-CBE3 is typically supplied as a film with a release liner. It can be cut into desired shapes, placed between components, and then heated or pressed to activate the adhesive.

Q: Can GF9450C-CBE3 be used for both manual and automated assembly processes? A: Yes, GF9450C-CBE3 is suitable for both manual and automated assembly processes, making it versatile for different production environments.

Q: Is GF9450C-CBE3 compatible with different substrates? A: Yes, GF9450C-CBE3 exhibits good compatibility with various substrates, including metals, ceramics, glass, and most plastics commonly used in electronics.

Q: What is the typical curing time for GF9450C-CBE3? A: The curing time for GF9450C-CBE3 can vary depending on the specific application and process parameters. It is recommended to follow the manufacturer's guidelines.

Q: Does GF9450C-CBE3 provide good long-term reliability? A: Yes, GF9450C-CBE3 is designed to offer excellent long-term reliability, ensuring stable electrical connections even under harsh operating conditions.

Q: Are there any safety precautions to consider when using GF9450C-CBE3? A: Yes, it is important to handle GF9450C-CBE3 in a well-ventilated area and follow the safety instructions provided by the manufacturer, including wearing appropriate personal protective equipment (PPE).

Please note that these answers are general and may vary based on specific product specifications and manufacturer recommendations.