Voir les spécifications pour les détails du produit.

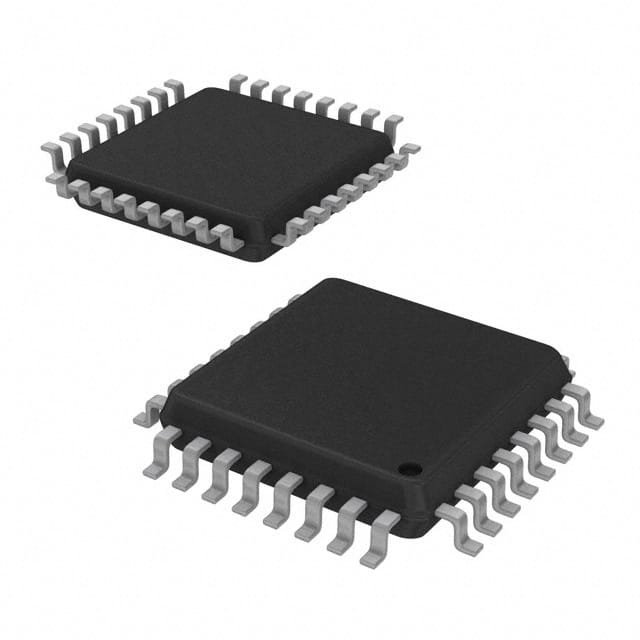

MPC961PAC

Product Overview

Category

MPC961PAC belongs to the category of integrated circuits (ICs).

Use

This product is commonly used in electronic devices for signal processing and control applications.

Characteristics

- Integrated circuit

- Signal processing and control capabilities

- Compact package size

- High reliability

Package

MPC961PAC is available in a small outline integrated circuit (SOIC) package.

Essence

The essence of MPC961PAC lies in its ability to process signals and provide control functions within electronic devices.

Packaging/Quantity

MPC961PAC is typically packaged in reels or tubes, with a quantity of 250 units per reel/tube.

Specifications

- Supply Voltage: 3.3V

- Operating Temperature Range: -40°C to +85°C

- Input Voltage Range: 0V to Vcc

- Output Voltage Range: 0V to Vcc

- Maximum Output Current: 100mA

- Package Type: SOIC-8

Detailed Pin Configuration

- Vcc (Power supply)

- GND (Ground)

- IN1 (Input 1)

- IN2 (Input 2)

- OUT (Output)

- NC (Not connected)

- NC (Not connected)

- NC (Not connected)

Functional Features

- Dual input operational amplifier

- Rail-to-rail input and output capability

- Low offset voltage and low noise

- Wide input voltage range

- High gain bandwidth product

Advantages and Disadvantages

Advantages

- Versatile and widely used in various electronic applications

- Compact size allows for integration into space-constrained designs

- High reliability ensures long-term performance

- Rail-to-rail capability enables accurate signal processing

Disadvantages

- Limited output current may restrict usage in high-power applications

- Not suitable for extreme temperature environments

Working Principles

MPC961PAC operates based on the principles of operational amplifiers. It amplifies and processes input signals, providing accurate and controlled output signals. The rail-to-rail capability allows it to handle a wide range of input voltages while maintaining precision.

Detailed Application Field Plans

MPC961PAC finds applications in various fields, including: 1. Audio amplification circuits 2. Sensor signal conditioning 3. Motor control systems 4. Data acquisition devices 5. Industrial automation

Detailed and Complete Alternative Models

- LM358: Dual operational amplifier with similar specifications and package type.

- TL072: Low-noise dual operational amplifier suitable for audio applications.

- AD822: Precision instrumentation amplifier for sensor signal conditioning.

These alternative models offer similar functionality and can be used as substitutes for MPC961PAC in different applications.

In conclusion, MPC961PAC is a versatile integrated circuit used for signal processing and control purposes. Its compact size, reliability, and rail-to-rail capability make it suitable for various electronic applications. However, its limited output current and temperature limitations should be considered when selecting this product.

Énumérez 10 questions et réponses courantes liées à l'application de MPC961PAC dans les solutions techniques

Sure! Here are 10 common questions and answers related to the application of MPC961PAC in technical solutions:

Q: What is MPC961PAC? A: MPC961PAC is a microprocessor-based controller used for advanced process control in technical solutions.

Q: What are the key features of MPC961PAC? A: The key features of MPC961PAC include multi-loop control, PID algorithms, data logging, communication interfaces, and advanced diagnostics.

Q: How can MPC961PAC be applied in technical solutions? A: MPC961PAC can be applied in various technical solutions such as industrial automation, robotics, HVAC systems, power generation, and chemical processing.

Q: Can MPC961PAC handle multiple control loops simultaneously? A: Yes, MPC961PAC is designed to handle multiple control loops simultaneously, allowing for efficient control of complex processes.

Q: Does MPC961PAC support PID control algorithms? A: Yes, MPC961PAC supports PID control algorithms, which are widely used for precise control of process variables.

Q: Can MPC961PAC communicate with other devices or systems? A: Yes, MPC961PAC has built-in communication interfaces such as Ethernet, RS485, and Modbus, enabling seamless integration with other devices and systems.

Q: Does MPC961PAC have data logging capabilities? A: Yes, MPC961PAC has data logging capabilities, allowing for the collection and analysis of process data for troubleshooting and optimization purposes.

Q: Is MPC961PAC suitable for applications requiring advanced diagnostics? A: Yes, MPC961PAC offers advanced diagnostics features, including fault detection, alarm notifications, and predictive maintenance capabilities.

Q: Can MPC961PAC be programmed and customized for specific applications? A: Yes, MPC961PAC can be programmed and customized using software tools provided by the manufacturer, allowing for flexibility in application development.

Q: Are there any limitations or considerations when using MPC961PAC in technical solutions? A: While MPC961PAC is a versatile controller, it's important to consider factors such as power requirements, environmental conditions, and compatibility with existing systems during the implementation process.